SDAR-OES&EDPXRF spectrometry, X-ray diffractometry and inferential metrology Laboratory

Room JK 104

Research Staff

Associate Professor Ion PENCEA

Lecturer Catalin SFAT

Expertise:

- SDAR-OES measurement on Fe, Mn, Al, Cu, Sn, Ti matrices.

- EDP-XRFS measurement on solid and liquid inorganic matrices;

- Specimen preparation for SDAR-OES and XRF measurements;

- Investigation and theoretical supporting of the solid state phase transformations into alloys

T

Collaborations

- X-ray Diffractometry Laboratory of the INCD-IMNRR Bucharest, Romania;

- X-ray Diffractometry Laboratory of the Applied Science Faculty of UPB, Bucharest, Romania;

- Spectrochemical Laboratory of the INCD-ICEM, Bucharest, Romania;

- C. SPECTRO SERVICE ROMANIA srl, Romania

- SC ELMICROSERV srl, Romania,

- SC CANBERRA PACKARD SRL, Romania

SPECTROMAXx - SDAR-OES Spectrometer

(SPECTRO Analytical Instruments Gmb H & co. KG, Germany)

Analytical performances:

- Analytical range: C =>U;

- LOD: 1—10ppm;

- LOQ: 5-20ppm;

- ROI: 5ppm—99%;

- RMU < 2 %;

- analytical programs: Ti, Fe, Al, Cu, Co, Sn, Mg, Ni, Ag;

- specimen prerequisites: disklike shape with a plane face of least 13mm in diameter

Referentials:

- EN ISO/CEI 17025: 2005- General requirements for the competence of testing and calibration laboratories

- ISO/IEC Guide 98-3:2008-Uncertainty of measurement -- Part 3: Guide to the expression of uncertainty in measurement (GUM:1995)

- ILAC-G24:2007 Guidelines for the determination of calibration intervals of measuring instruments;

- ILAC-G9-2005- Guidelines for the Selection and Use of Reference Materials

XEPOS – EDP-XRF Spectrometer

(SPECTRO Analytical Instruments GmbH)

Specific characteristics:

Optimum excitation, using polarization and secondary targets, complex support for 8 or 12 samples and software modules, make the unit one of the most versatile elemental analyzer available on the market.

The spectrum of applications includes, among others, the analysis of: metals, slag, waste, sludge, concrete, refractory materials, electronic components, soil, food, liquid (water, soft drinks, alcoholic beverages, oil products etc).

Analytical performances:

- Analytical range: Na to U;

- LOD: 1—10 ppm, depending on element and specimen matrix and preparation;

- LOQ: 5-20 ppm,

- ROI: 5ppm—99%, ibid.

- RMU < 2 %; ibid.

- analytical programs: TurboQuant Alloy; TurboQuant Powder; TurboQuant Pellet; TurboQuant Liquid; Fundamental Parameters.

- specimen prerequisites : solid specimens: disk-like shape with a plane face of least 30 mm in diameter; powdered sample: minimum 10g powder; liquid samples: minimum 50 ml.

Laboratory Referentials for XRFS:

- EN ISO/CEI 17025: 2005- General requirements for the competence of testing and calibration laboratories

- ISO/IEC Guide 98-3:2008-Uncertainty of measurement -- Part 3: Guide to the expression of uncertainty in measurement (GUM:1995)

- ILAC-G24:2007 Guidelines for the determination of calibration intervals of measuring instruments;

- ILAC-G9-2005- Guidelines for the Selection and Use of Reference Materials

Method Standards for XRFS measurements:

- EN ISO 12677: 2003- Chemical analysis of refractory Products by XRFS;

- EN ISO 15309:2007- Characterization of waste and soil - Determination of elemental composition by X-ray fluorescence;

- ASTM E 1621-94 (R 2014)- Standard Guide for XRF spectrometry

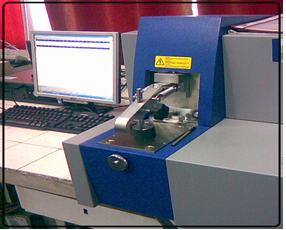

FOUNDRY MASTER - SDAR-OES Spectrometer

(WAS Worldwide Analytical Systems AG, Germany)

The main technical characteristics of optical emission spectrometer Foundry Masters are:

- Spectral source (spark); analysis is performed mainly how-SDAR HEPS (High Energy Spark Discharge PreSparking- Argon 15kV, 200 Hz);

- Compact vacuum system (vacuum pump RZ-2); p ~ 10.3 bar;

- 160-460nm spectral analysis;

- Detectors CCD (Charged Couple Device) which converts mood guaranteed semiconductor light signals into electrical signals Digital - 16 interlaced CCDs Rowland circle placed on the appliance;

- High purity argon atmosphere (5.3-6.0) for electrical discharge;

- Standards recalibration UP (Set Up Samples) supplied with the machine by producing company for "degrees" APIs: Based Fe base Cu, Ti basis, based Al, Ni base.

Analytical range:

The FOUNDRY MASTER has specific analytical programs (specific calibration curves) for elemental analysis of about all industrial metallic grades e.g. low alloy steels, Ni base alloys, Cu based alloys , Al base alloys, Ti base alloys and Co-Cr base alloys.

Educational activities

“SDAR-OES&ED(P)-XRF spectrometry, X-ray diffractometry and inferential metrology Laboratory” is the main infrastructure of the “Materials Testing Science and Management” master program, designed to provide specialists for accreditated/accreditable laboratories.

Laboratory practice supporting the courses addressed to bachelor students as follows:

- Materials’ Quality Management;

- Materials’ study;

- Structural Theory of the Material Properties;

- Measurement Methods Validation;

- Measurement Uncertainty Estimation;

- Materials Spectrochemical Analysis by OES and XRFS Methods;

- Materials XRD Analysis;

- The Fitness for Specific Purposes of the Metallic Materials.

- Biomaterials;

- Advanced Materials.

Laboratory practice supporting the courses addressed to master students as follows:

- Laboratory nvestigations for graduation thesis

- Laboratory investigations for PhD thesis

- Laboratory measurements for third parties e.g. Koyo, Daimler-Benz, Timken, Mechel, Romanian Custom Authority, Romanian Skeleton Federation, Romanian Railway Authority etc.

Training activities:

- Specimen preparation for XRD, XRF and SDAR-OES measurements

- XRD, XRF and SDAR-OES equipments operation.

- Designing of the MU budget depending on specific technique and operating conditions

- Estimation of the MU according EN Guide 98-3: 2010

- Quality system design for testing laboratories according to EN ISO/CEI 17025:2005;

- Statistical inference for measurement results analysis;

- Method validation procedures

- Laboratory quality system audit

- Round-Robin inter-laboratory comparison testing

Research activities:

- TiAlN, TiN, TiCN, TiAlN and enamel coating characterization

- Structural and elemental characterization of the high entropy alloys and of their precursors

- Rapid solidified Al-base alloys for high temperature application in aeronautical and automotive industries

- Fundamental researches on improving LOD, LOQ and MUE of the analytical methods in the frame of the GUM approach

- Procedures for XRD, XRF and SDAR-OES methods and their validation